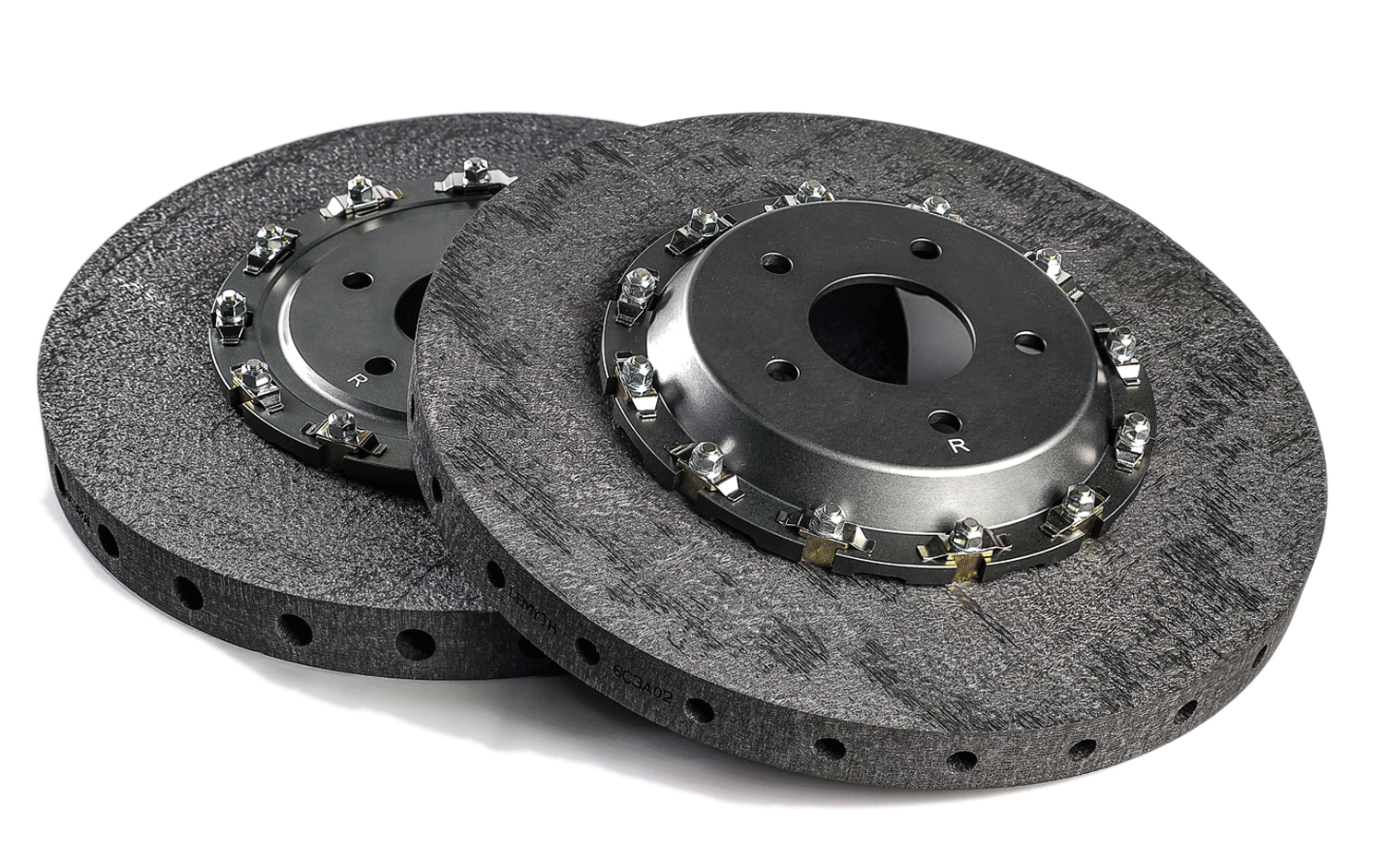

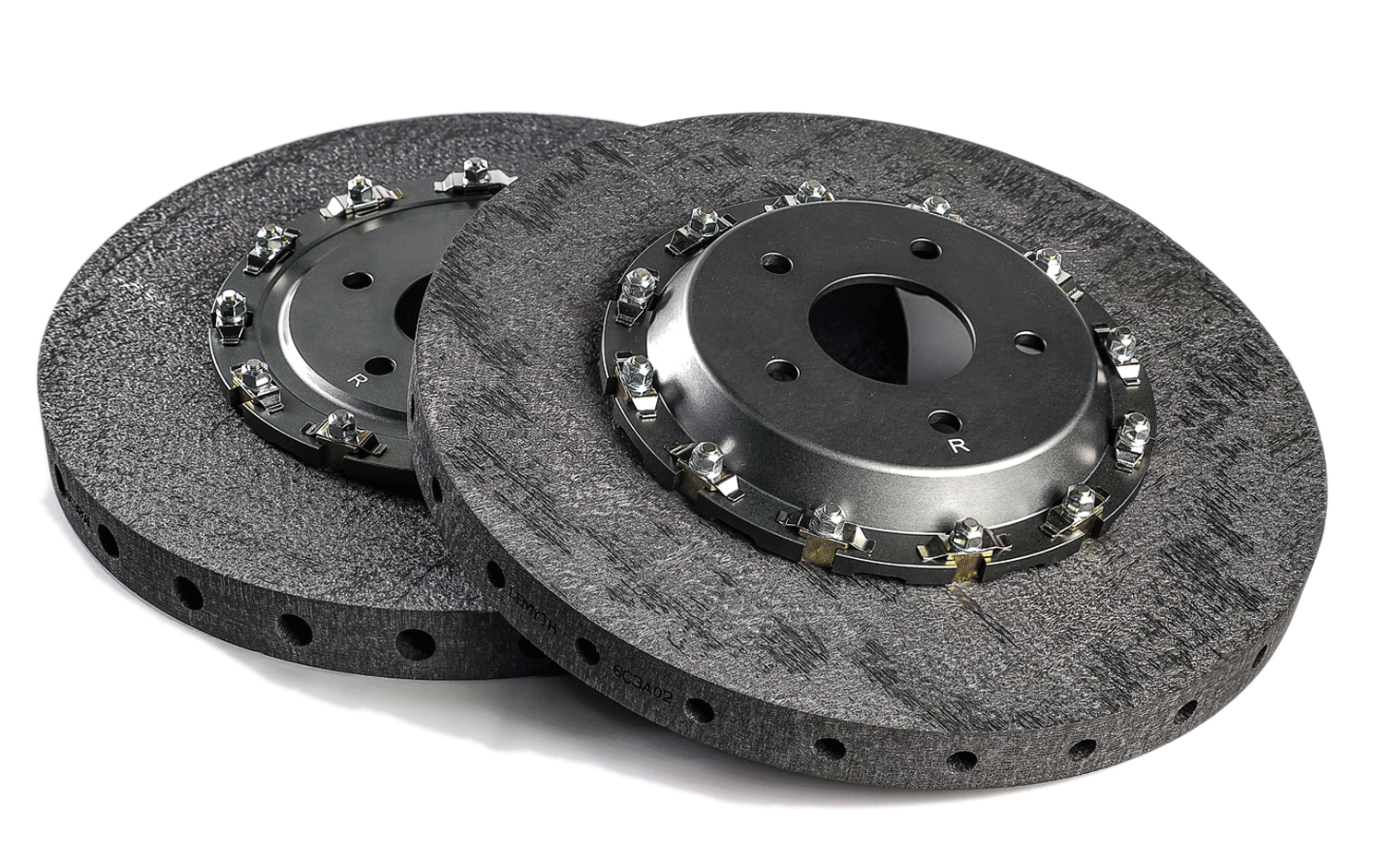

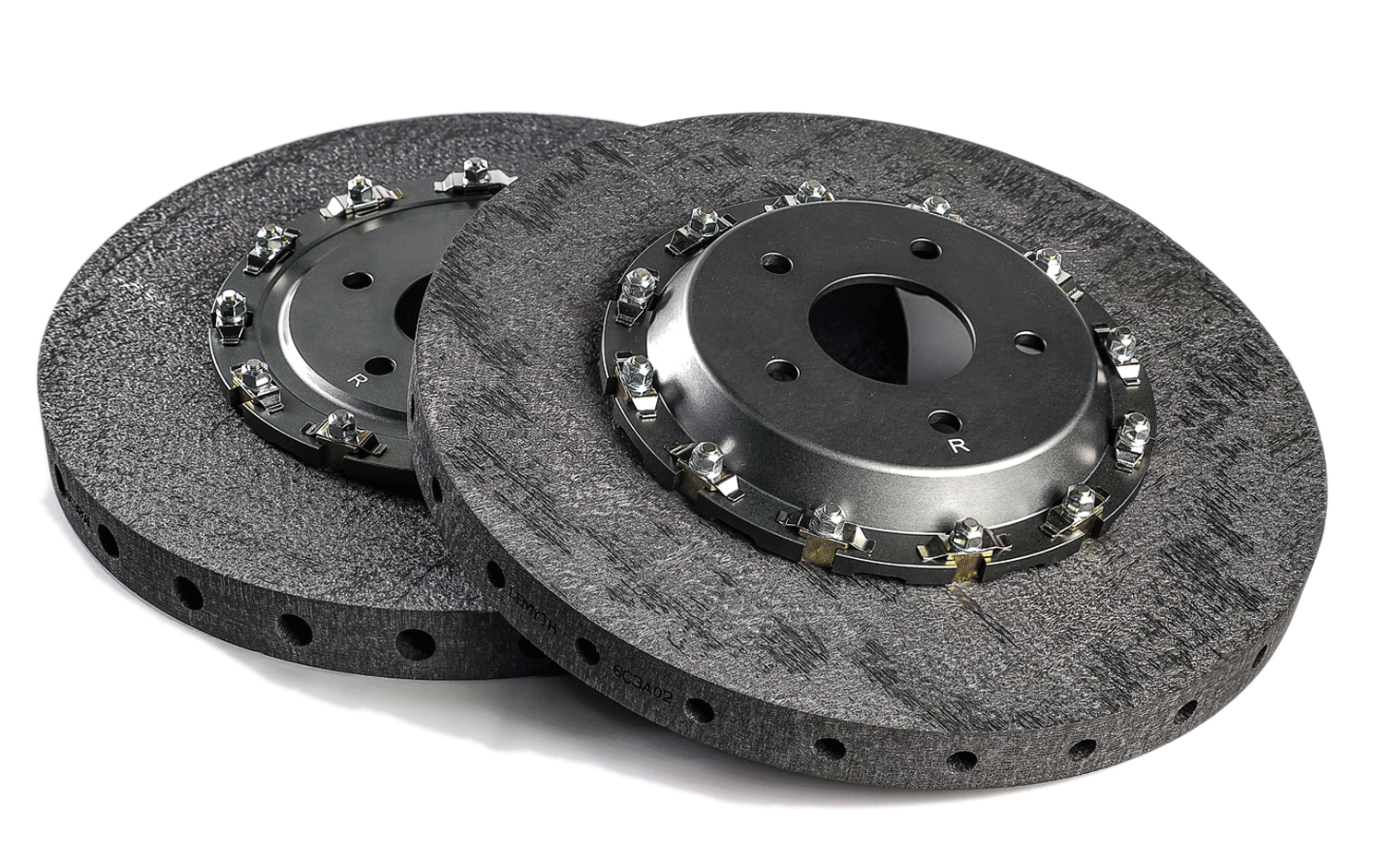

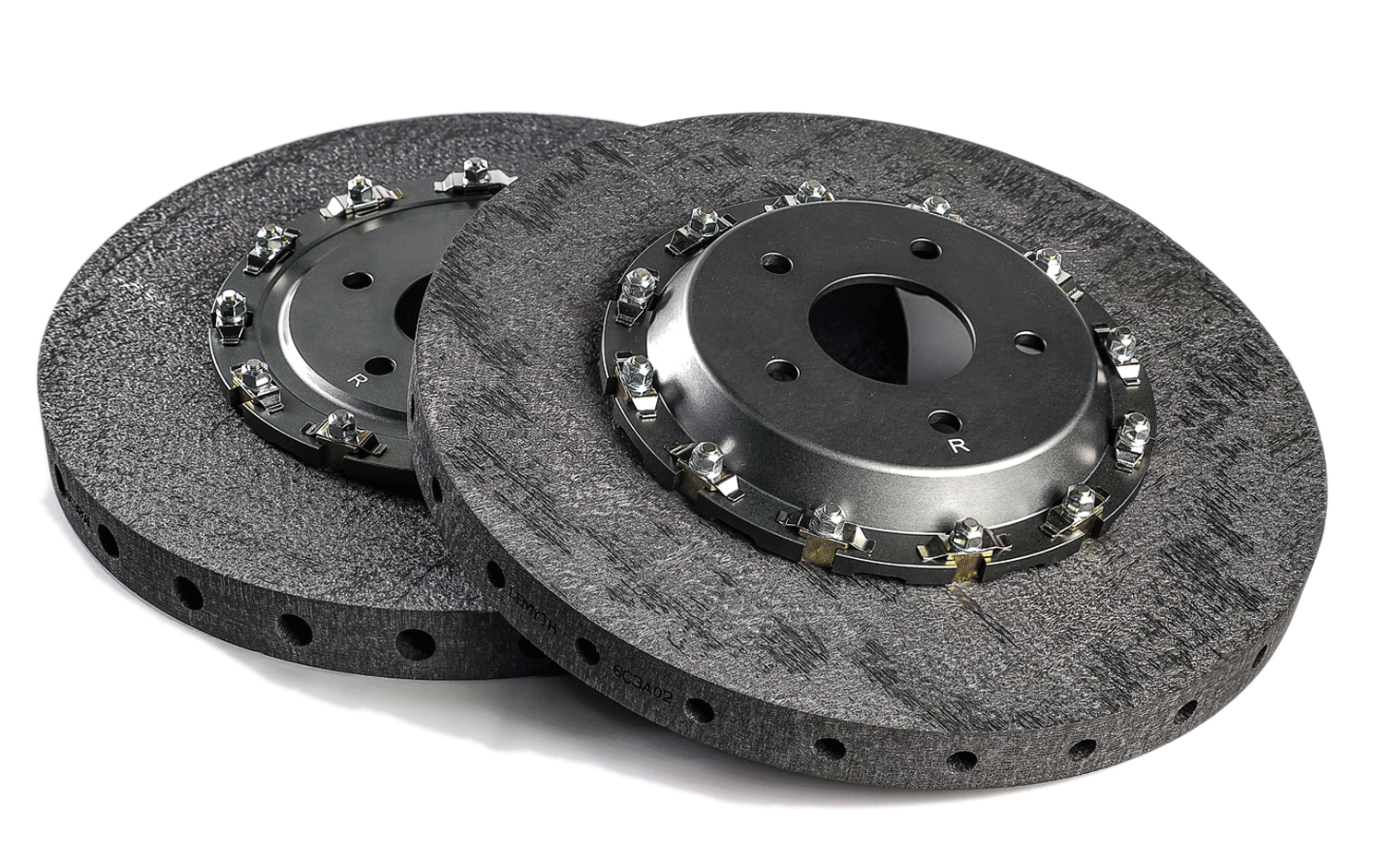

Next-generation C/SiC braking technology for racing, luxury, and special utility vehicles. 70% lighter than steel, 3x longer lifespan. Engineered for ultimate stopping power.

At CMCMAT, we specialize in the manufacturing of advanced continuous fiber Carbon Ceramic (C/SiC) brake rotors. Unlike traditional iron discs, our carbon ceramic brakes are composed of a carbon fiber-reinforced silicon carbide matrix. This aerospace-grade material offers exceptional thermal stability and mechanical strength.

Designed for the most demanding automotive applications, our CCB rotors are the ideal upgrade for global brake brands, racing teams, and automotive distributors looking for premium performance solutions. We offer complete kits including carbon ceramic discs and bespoke center bells (hats).

We supply carbon ceramic brakes for many different car models, no matter replace stock carbon ceramic rotors or upgrade origianl steel rotors to carbon ceramic discs. And customization dimension rotors are also avialable.

Showing the single result

Reduces unsprung weight by up to 70% compared to steel rotors, significantly improving vehicle handling, acceleration, and fuel efficiency.

Withstands temperatures over 1,600°C without brake fade. Consistent braking performance during intensive track use or continuous downhill driving.

Offers 3 to 5 times the service life of traditional cast iron discs (300,000+ km under normal driving conditions), reducing long-term replacement costs.

Say goodbye to corrosive brake dust. Carbon ceramic materials keep your wheels clean and maintain the aesthetic appeal of high-end vehicles.

As a dedicated manufacturer, CMCmat supports B2B partners with comprehensive customization services. We understand that one size does not fit all.

A: Carbon Carbon brakes are primarily used for aircraft and Formula 1 cars; they require high temperatures to work effectively and are not suitable for street use. Carbon Ceramic (C/SiC) brakes, which we supply, are designed for automotive use. They offer excellent cold bite, making them effective for both street driving and track use.

A: No. You must use specific brake pads formulated for carbon ceramic discs. Using standard semi-metallic or ceramic pads designed for steel rotors can damage the CCB surface. CMCmat can recommend or supply compatible high-performance pads.

A: Yes, we are an export-oriented manufacturer. We ship our carbon ceramic brake kits globally to MROs, distributors, and modification shops via air freight or sea freight, ensuring safe packaging to prevent damage during transit.

Contact our technical sales team today for a catalog, price list, or to discuss your custom project requirements.

Carbon ceramic (C/C-SiC) brakes and steel brakes are two different types of braking systems used in the automotive industry, each with its own distinct properties and best use cases.

Material Composition:

Performance:

Durability:

Cost:

Maintenance:

Application:

Material Composition:

Performance:

Durability:

Cost:

Maintenance:

Application:

Choosing between carbon ceramic and steel brakes typically comes down to the specific needs and usage of the vehicle, balancing factors like cost, performance requirements, and vehicle type.

Note: Your email information will be kept strictly confidential.