Carbon Carbon and Carbon Ceramic Composite and Applications

Aircraft Carbon Heat Pack and Automobile Carbon Ceramic Brake Rotors

Light Weight and High Heat-Resistant Carbon matrix Composite

Cost Effective

Designed for durability and efficiency, you can get long-term value across various high-demand applications.

Focus on Quality

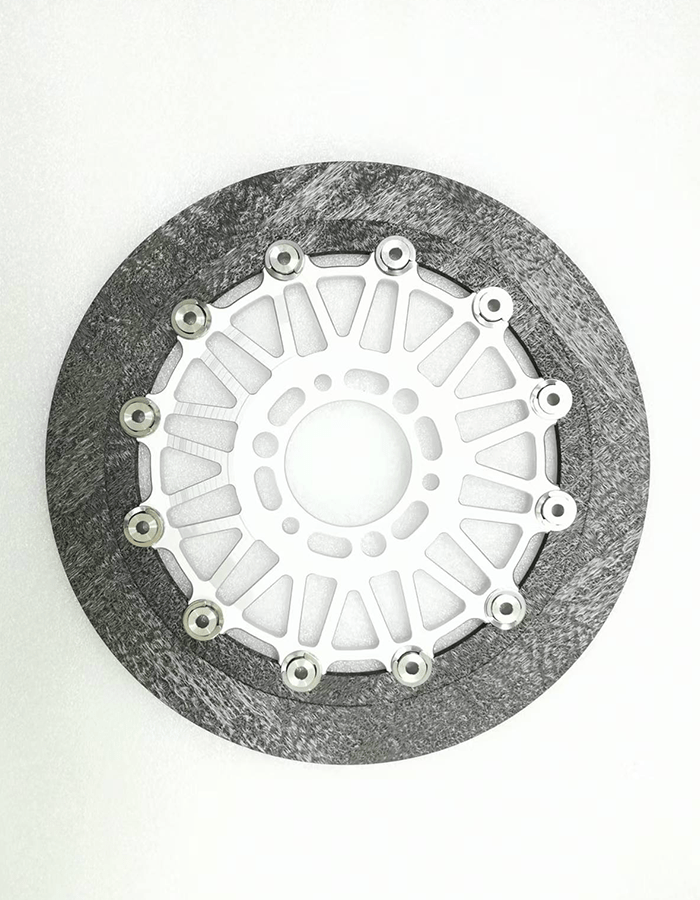

All the aircraft carbon carbon parts are certified, and all the carbon ceramic brakes are proved by different customers.

Ready to save your cost with our higher performacne parts?

ABOUT US

From Aviation to Automobile,

Brake Parts Based on Carbon Carbon and Carbon Ceramic materials.

Shenzhen CMC Composite Co., Ltd (CMCMAT) is a leading innovator in the production and development of advanced carbon-ceramic and carbon-carbon materials. Renowned for our commitment to quality and technological excellence, CMCMAT has earned a distinguished reputation in the aerospace, aviation, and automotive industries. Our state-of-the-art materials are engineered to meet the highest performance standards, making us a trusted partner for cutting-edge applications worldwide.

Our Partners

OUR PRODUTS AND SERVICES

Discover Our Carbon Composite Solutions and Services

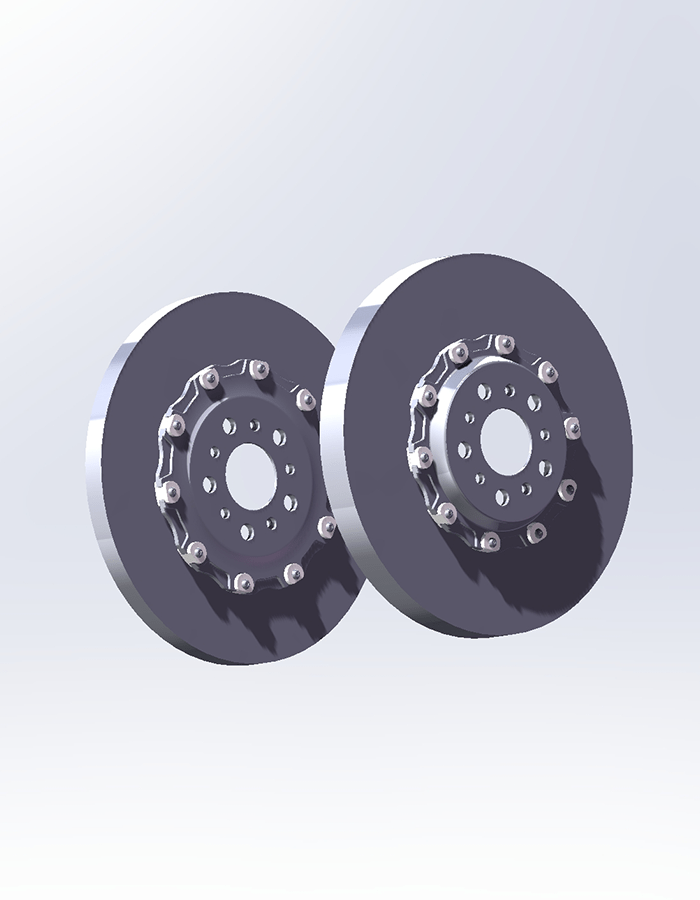

At CMCMAT, we provide our valued customers with high-quality yet cost-effective carbon products. Our offerings include C/C heat sinks for aircraft, carbon-ceramic brake rotors and pads for automotive applications, and high-density carbon-carbon composites for throats and nozzles. Additionally, we offer customization and R&D services tailored to your specific requirements.

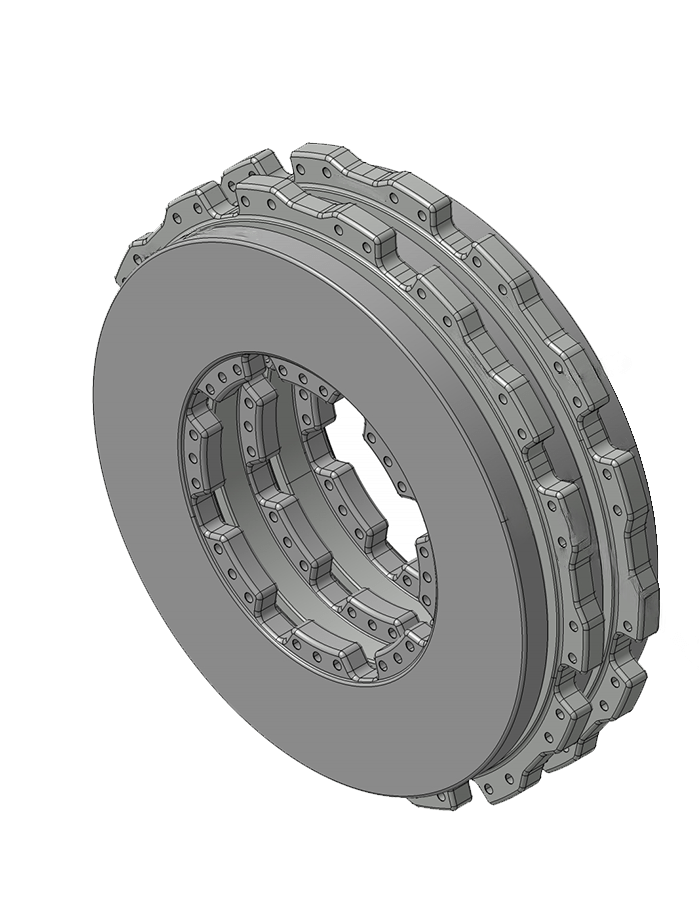

C/C Heat Packs

Carbon Ceramic Brakes

High Density C/C Parts

More About Our Services and Products

HOW IT WORK

The Main Steps to Develop a Carbon Application

We will review the drawings, manufacture the carbon composites, machine them into the required shape, and apply an anti-oxidation coating to the finished carbon parts.

Get correct applications call us!

Contact Us Today

+86-13823149826

Review Drawings

Our engineers will review the drawings when we recieved them from the customers.

Carbon Fiber Preforms

Produce carbon fiber preforms with sufficient machining allowance.

Densification

Put the suitable carbon fiber preforms into the oven for densification. We have CVI/ CVD and LPI process for this step.

CNC Machining

The density reached carbon parts will be machined into the final parts as the drawings required.

Anti-Oxidate Coating

Before assembling them with hardwares, all carbon parts will have to be anti-oxidation coated.

CASE STUDY

Custom Solutions for Unique Applications

We specialize in developing carbon brakes for both aircraft and automobiles, as well as high-temperature and ablation-resistant carbon components.

Clients Comments

Discover What Our Clients Say About Our Products and Services

Why 100+ Customers Trust CMCMAT?

- Competitive Prices: Efficient supply chains keep our prices competitive.

- Unmatched Quality: Certified, top-quality products from seasoned suppliers.

- Fast Turnaround: Quick, reliable delivery for all order sizes.

- Skilled Team: Decades of industry expertise supporting your needs.

FAQs FOR CLIENT

Getting Started with Our Company

We are a supplier of aircraft carbon brakes and automotive carbon-ceramic brakes. Additionally, we specialize in developing custom carbon components for various applications.

Get In Touch

We have the full knowledge to develop carbon brakes for your aircrafts and vehicles!